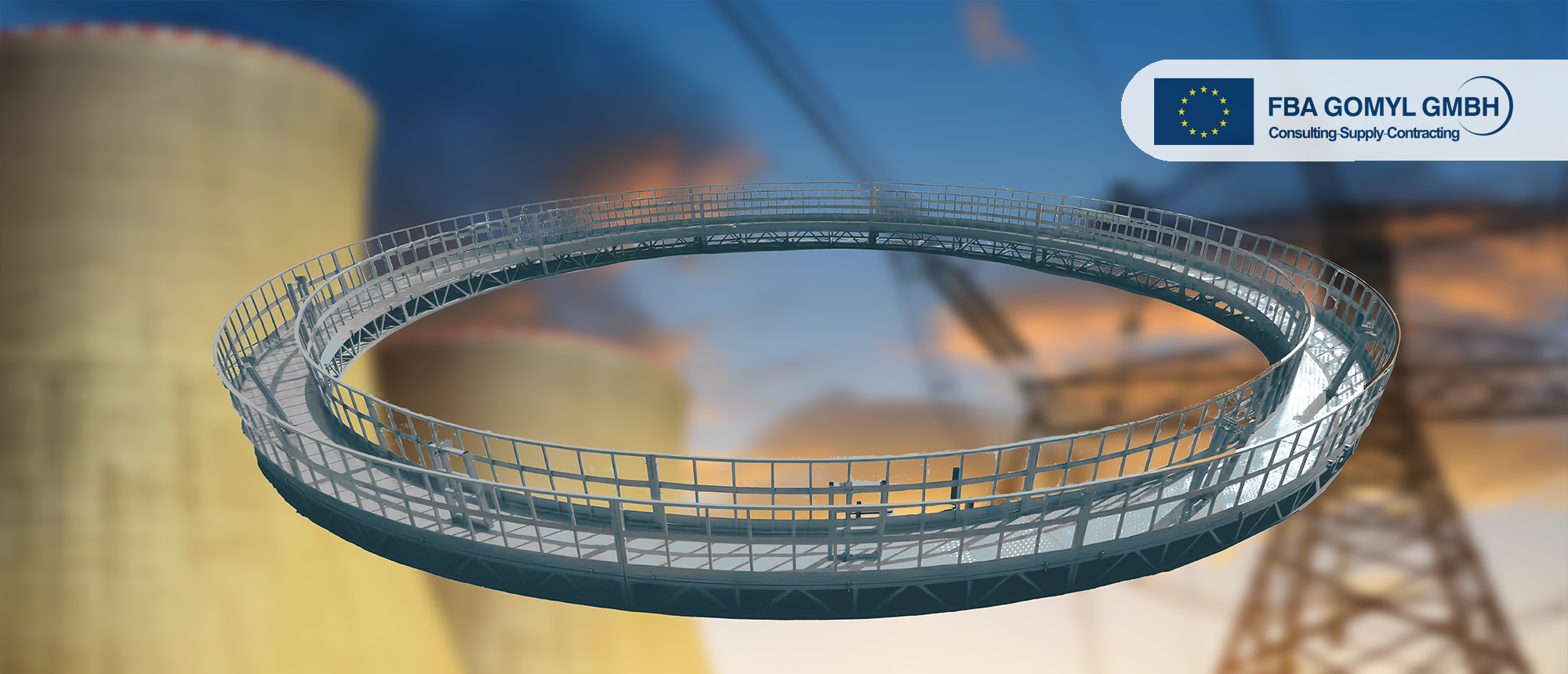

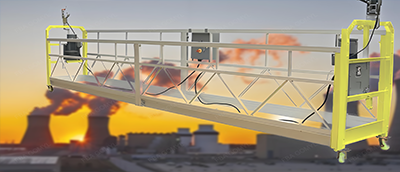

吊篮维修平台

遵循轨道或钢丝绳爬升 异型标准模块组装

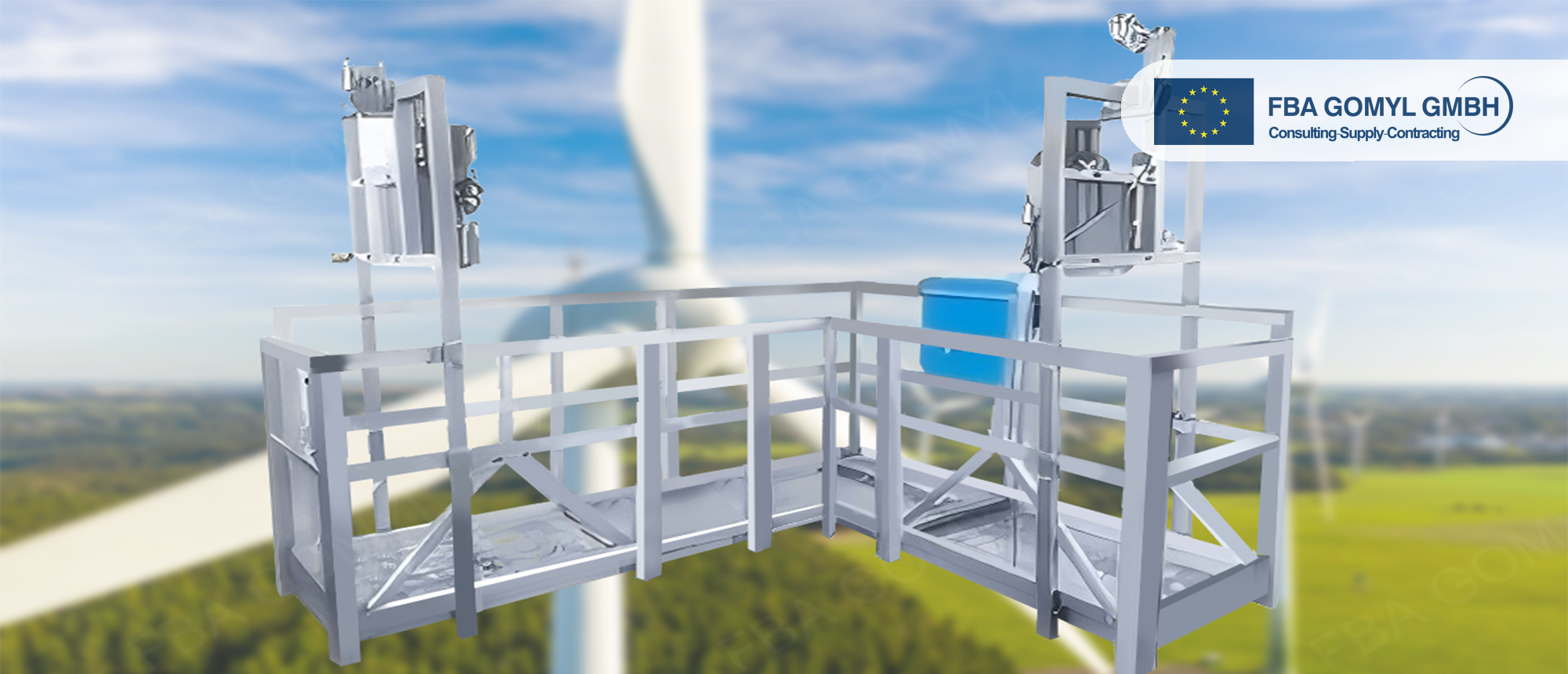

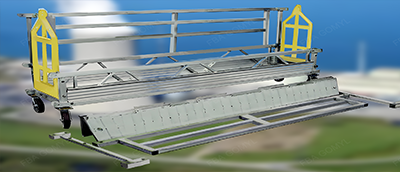

全安斯福FBAGOMYL升降吊篮平台,利用简便快捷的模块化吊篮,可进入较小、难以达到的工作现场。升降专用吊篮部件可通过45厘米或更小的通孔便捷折叠运输。无需投入昂贵的人工和安装成本来堆叠和搭建异型维修平台系统。可以广泛服务于锅炉、风电和桥梁的日常维修保养工作。

在狭小工作环境内,2至3名工人可在数十分钟内完成3至9米异型吊篮的组装。

想象一下,使用模块化吊篮可以节省大量时间。此外,我们提供并推荐专业且安全的培训。全安斯福FBAGOMYL升降吊篮平台的特点及用途

通过对45厘米或更小的通孔进行折叠运输。

3米到9米异型平台的最大承载重量为1000千克。

额定负载为454公斤,异型高度在1米至9米之间

小型卡车可以搬运9米(或更长)的吊篮。

利用门以及可移动的边框,可以实现更多的功能。

工人可以在数十分钟内组装好吊篮。

使用不同的组件来创建适应各种尺寸和具有多样性能的异型吊篮。

增加扶手的调节功能,从而增加更多的操作选项,扩大作业区域。

可供选择的规格尺寸繁多。

符合或超出所有OSHA和ANSI标准,

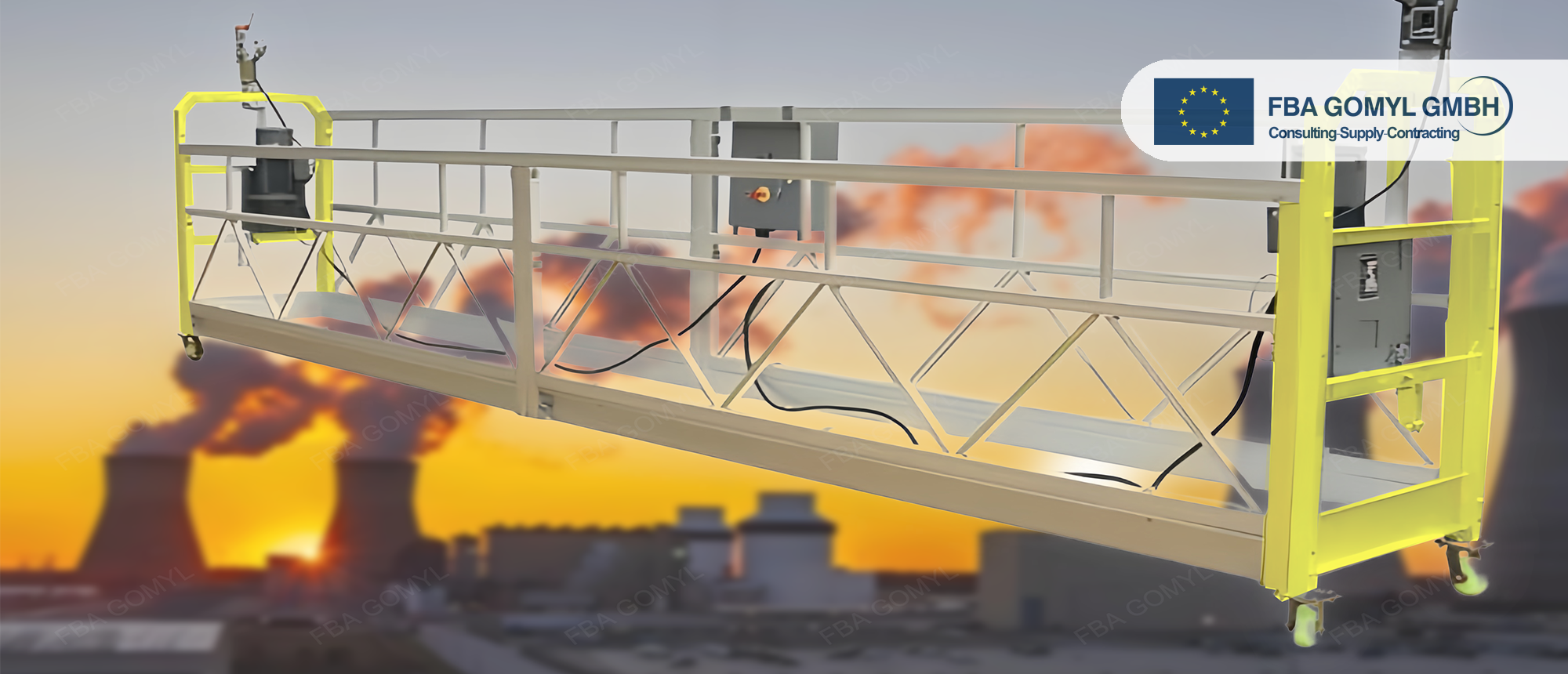

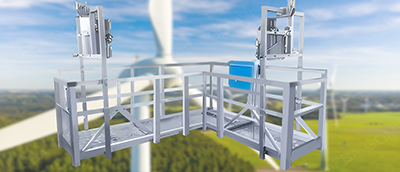

POWERED CRADLE PLATFORM

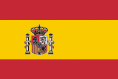

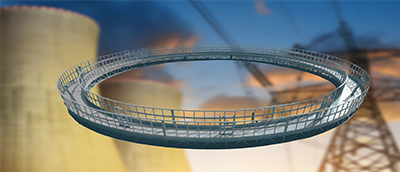

The furnace maintenance cradle cage has been innovatively designed, not only with a stable body structure, but also cleverly equipped with guide rods at both ends. Rolling structures are installed on the guide rods, and a directional wheel design is adopted. This directional wheel is set along the direction of the guide rod, which helps the cage to roll and stabilize during operation. It is worth mentioning that the bottom of the body is also equipped with efficient rollers, which adopt a universal wheel design, making it more convenient to push the cage on the ground.

The introduction of this new practical device significantly improves the overall performance of the suspended basket. Not only does it help ensure stable operation of the basket at high altitude, but it also allows the directional wheel to roll along the surface of the cooling tower, boiler, or chimney, effectively reducing the inconvenience caused to operators by basket shaking. Compared to traditional hanging baskets, this new device not only improves the safety of workers, but also enhances work efficiency, making operations more convenient and efficient.